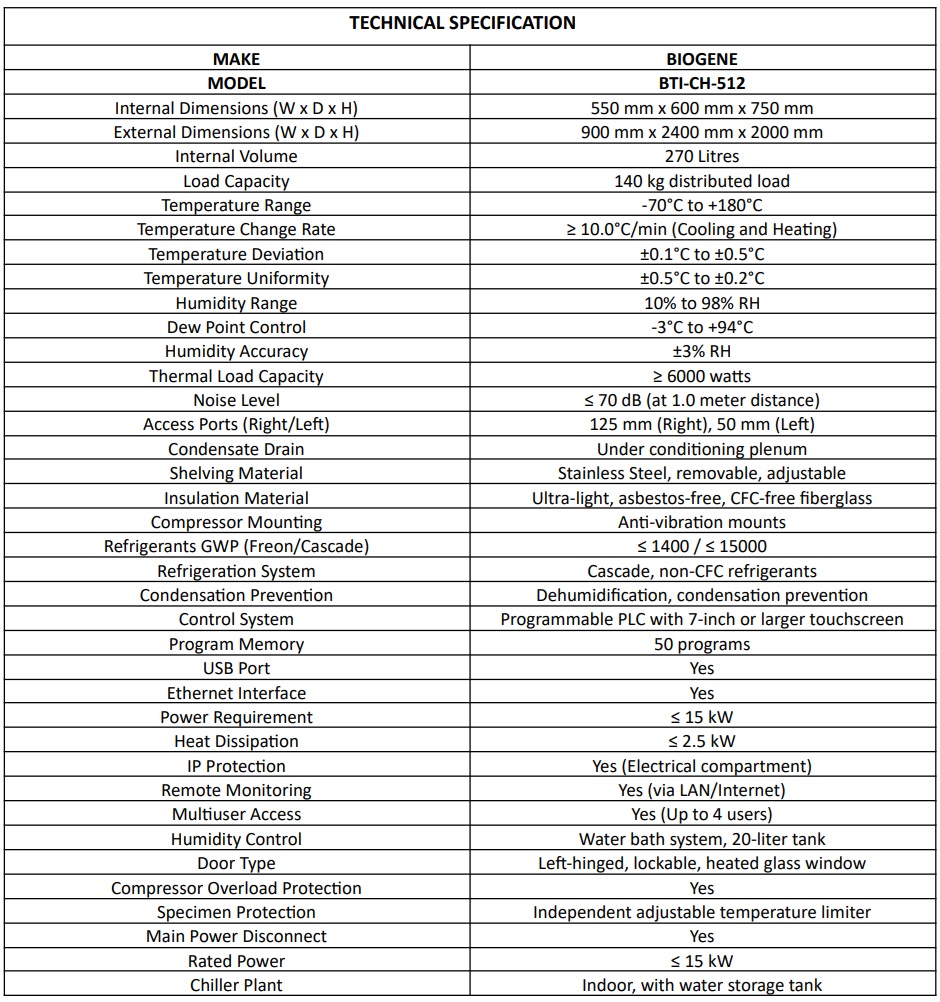

Thermal Cycling Chambers by Biotechnologies Inc. are engineered for high-precision thermal shock testing, temperature and humidity cycling, and environmental stress screening. As a top-tier thermal cycling chamber manufacturer in India, our systems support rapid ramp rates and ±0.1°C accuracy and also support high ramp rates and low ramp rates, e.g., 0.1°C to 25°C, and uniform thermal conditions. These chambers are ideal for the automotive, aerospace, electronics, and materials testing industries. With customizable controls, real-time data logging, and compliance with global test standards, BioGene delivers dependable cyclic temperature chamber solutions built for durability, efficiency, and performance.

The Bio Gene Thermal Cyclic Chamber is designed to deliver highly controlled environmental simulations for research, quality control, and stress testing applications. It integrates advanced temperature, humidity, and thermal cycle control with high precision, making it suitable for various industries such as aerospace, electronics, automotive, and material science. The chamber complies with stringent global standards, ensuring reliable, repeatable, and accurate test results.

Anti-Vibration Feet: The chamber is equipped with specialized anti-vibration feet to absorb operational vibrations. This feature is especially important during sensitive tests that require a stable environment, such as in electronic or material testing. By minimizing vibrations, the chamber ensures more accurate and consistent test results while also prolonging the life of internal components.

Low Noise Operation: The chamber operates at a noise level of ≤ 70 dB, measured at a distance of 1 meter, in accordance with EN ISO 11201:2010. This low noise level ensures that the chamber can be comfortably used in laboratory environments without causing disruption. It is particularly beneficial in workspaces where noise-sensitive operations are conducted alongside testing.

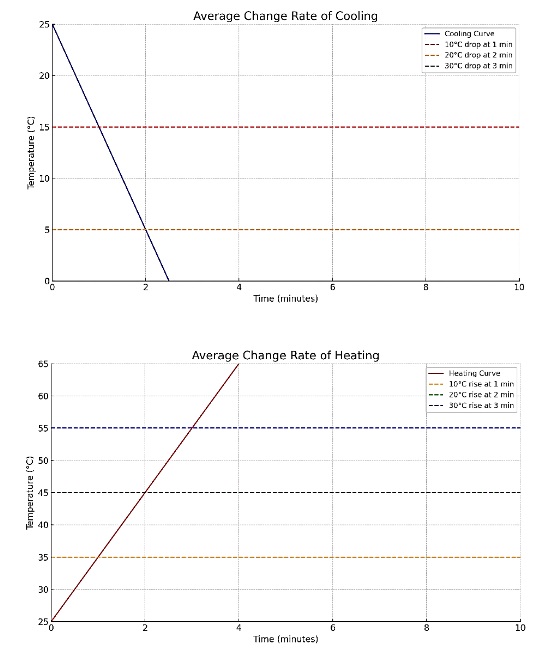

Rapid Temperature Cycling: The chamber is designed for fast temperature changes, with a cooling rate and heating rate of ≥ 10.0°C/min. This capability is essential for Environmental Stress Screening (ESS) tests, where rapid temperature cycling is used to detect product failures. The high-efficiency cooling and heating system ensures that the chamber can simulate extreme environmental conditions within a short period.

Precise Temperature Regulation: After reaching the set temperature, the chamber maintains a deviation of only ±0.1°C to ±0.5°C at the control sensor. This high level of precision is critical for tests that require stable temperature conditions over extended periods, such as materials testing or thermal stability analysis.

Temperature Homogeneity: The temperature uniformity within the chamber is controlled within ±0.5°C to ±0.2°C across the entire test space. This ensures that the temperature is consistent throughout the chamber, providing reliable and repeatable test results, regardless of where the test sample is placed.

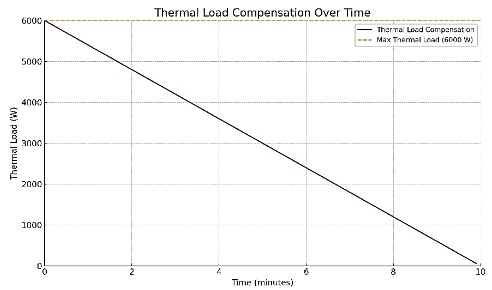

High Thermal Load Capacity: The chamber is capable of handling thermal loads of 6000 watts or more, allowing it to maintain stable conditions even when subjected to heavy thermal demands. This is particularly useful in tests that involve heating large or highly heat-absorbent objects.

Temperature Range: The system operates within a temperature range of +10°C to +95°C, allowing for tests that simulate various climatic conditions, from mild environments to extreme heat.

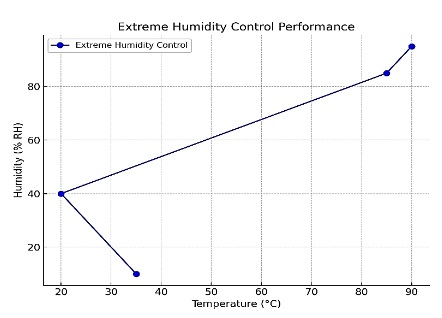

Humidity Range: The chamber can maintain humidity levels between 10% and 98% Relative Humidity (RH). This wide range is suitable for a variety of tests, including those requiring dry conditions as well as those simulating tropical or highly humid environments.

Dew Point Control: The dew point temperature is controlled from -3°C to +94°C. This is essential for preventing condensation on samples and maintaining accurate test conditions during high-humidity tests.

Precision Humidity Regulation: The system maintains a humidity accuracy of ±3% RH, ensuring precise control over the environmental conditions. This accuracy is critical for humidity-sensitive tests, such as those involving electronic components or moisture-sensitive materials.

Humidification System: The chamber uses a water bath humidification system, which includes a built-in 20-liter demineralized water tank. This system ensures a continuous supply of humidity, with alarms to notify the user if water levels are low. The humidification system is particularly useful for tests that require extended periods of high humidity, such as corrosion tests.

Dehumidification System: Advanced dehumidification features prevent condensation from forming on test samples. This is important in tests where moisture could affect the integrity of the sample, such as electronic components or sensitive materials.

Ice Formation Prevention: The system is designed to prevent ice from forming within the chamber, even during extreme humidity tests. This feature helps maintain consistent environmental conditions and protects the chamber’s internal components.

Cascade Refrigeration System: The chamber is equipped with a cascade refrigeration system that uses eco-friendly, non-CFC refrigerants. This environmentally responsible design helps reduce the global warming potential (GWP) of the chamber’s operation.

Refrigerant Compliance:

The Freon refrigerants used have a GWP of ≤ 1400.

The cascade refrigerants have a GWP of ≤ 15000, meeting stringent environmental standards.

Compressor: The compressor is mounted on anti-vibration mounts to ensure quiet, efficient operation. The compressor also includes overload protection, which prevents damage to the system in the event of electrical or operational surges.

Water-Cooled Condenser: A water-cooled condenser is located at the base of the chamber, offering high cooling capacity. This condenser ensures efficient heat exchange, enabling the chamber to rapidly cool to the desired temperature, even in demanding test conditions.

User-Friendly Touchscreen Interface: The chamber’s control system features a 7-inch (or larger) touchscreen interface. This intuitive interface allows users to easily access all functions, monitor test progress, and adjust test parameters. The graphical display includes real-time data for temperature, humidity, and other process values.

Multiple Program Storage: The control system can store up to 50 customizable programs. Each program can include various temperature, humidity, and cycle conditions, making it easy for users to run repetitive or complex test sequences.

Real-Time Data Display: The chamber provides real-time graphical displays of temperature and humidity conditions. This allows users to track changes in environmental conditions throughout the test and ensures accurate data logging for analysis.

Remote Control: The chamber can be controlled remotely via a PC or tablet using an internet connection. This feature is particularly useful for long-duration tests, as it allows users to monitor and adjust test parameters from a remote location.

Multiuser Functionality: The system supports simultaneous access for up to four users, enabling collaborative testing environments. Multiple users can view test data, make adjustments, or monitor test progress without interrupting the overall operation.

Error Logging: The control system includes a comprehensive fault diagnosis feature, which logs errors and actions with timestamps. This feature aids in troubleshooting and ensures that any malfunctions are quickly identified and resolved, minimizing downtime.

RoHS and CE Compliance: All electrical components within the chamber meet RoHS (Restriction of Hazardous Substances) and CE (Conformité Européenne) standards, ensuring that no hazardous materials are used. This compliance also guarantees the chamber is safe to operate in various industrial and research environments.

Main Power Disconnect: The chamber is equipped with a main power disconnect switch, which allows for immediate power shutdown in the event of an emergency or during maintenance.

Overload Protection: Each electrical circuit is protected by fuses, circuit breakers, or heat limits. These protective features prevent electrical overloads, ensuring both user and equipment safety during operation.

Independent Temperature Limiter: The chamber is equipped with an independent adjustable temperature limiter. This safety feature allows users to set an upper temperature limit to protect test samples from overheating during the test process. If the temperature exceeds this limit, the system will automatically shut down to prevent damage to the samples.

The chamber includes a USB port for easy data export. This feature allows users to transfer test data for further analysis or record-keeping purposes, ensuring that test results can be easily shared or archived.

The Ethernet interface provides seamless integration into a local area network (LAN), enabling remote monitoring, data sharing, and control over the chamber from any network-connected device.

PC Software: The chamber comes with dedicated PC software for data logging and remote monitoring. The software allows users to view real-time test conditions, control the chamber remotely, and log data for further analysis. This feature is especially useful for long-duration tests, where continuous monitoring and data recording are essential.

Rated Power: The chamber consumes up to 15 kW of power during operation, offering a balance between performance and energy efficiency. This energy efficiency ensures that the chamber is suitable for long-term operation without incurring excessive energy costs.

Heat Dissipation: The system is designed to limit heat dissipation into the surrounding environment to 2.5 kW. This reduces the impact of the chamber on laboratory or industrial environments, ensuring that surrounding equipment or personnel are not affected by excessive heat.

Electrical Compartment: The electrical compartment of the chamber is protected by IP-rated enclosures, ensuring resistance to dust and moisture. This added layer of protection increases the durability and safety of the system, especially in environments with high humidity or dust levels.

Internal Workspace: The internal dimensions are 550 mm (W) x 600 mm (D) x 750 mm (H), providing a total capacity of 270 liters. This workspace is ideal for testing small-to medium-sized products or components, allowing for precise environmental simulations across a variety of applications.

External Dimensions: Externally, the chamber measures 900 mm (W) x 2400 mm (D) x 2000 mm (H), compact enough for most laboratories and industrial facilities while still offering a spacious interior for testing.

Load Capacity: The chamber is engineered to support various load capacities depending on the distribution. It can handle up to 140 kg of distributed load across the test space, accommodating heavier samples or equipment. Shelves and racks within the chamber are also designed to support significant weight while maintaining stability and uniform test conditions.

Ergonomic Design: The chamber features a left-hinged door that is lockable for secure closure, providing optimum contact pressure. The door is engineered for one-handed operation, allowing users to easily open and close the chamber while handling samples or tools. This ergonomic design also ensures a tight seal, minimizing the risk of temperature or humidity fluctuation.

Multi-pane Glass Window: The chamber is equipped with a multi-pane glass window in the door, which is heated to prevent condensation. This feature allows users to monitor tests in real-time without opening the chamber, thereby maintaining the controlled internal environment. The heating mechanism ensures clear visibility, even during high-humidity tests.

Interior: The inner walls of the chamber are constructed from high-grade stainless steel (1.4301), known for its corrosion resistance and durability, making it suitable for long-term exposure to extreme temperature and humidity conditions. The floor is made of stainless steel 1.4404, which offers enhanced resistance to chemical corrosion and wear, especially important when dealing with various industrial or chemical test conditions.

Exterior: The chamber’s exterior is made from double-coated galvanized steel, offering excellent corrosion resistance. This ensures the chamber's durability in different environments, protecting it from rust, mechanical wear, and environmental factors over time. The external coating is also designed for easy cleaning and maintenance, making it suitable for use in industries with strict hygiene standards.

Fiberglass Insulation: The chamber is insulated with ultra-light, asbestos-free, and CFC-free fiberglass material. This material has very low thermal conductivity, which reduces heat loss and improves the energy efficiency of the chamber. The insulation is critical for maintaining stable internal temperatures, especially during rapid heating or cooling cycles. It also prevents external temperature influences from affecting the test results.

Adjustable Shelves: The chamber includes stainless steel shelves that can be adjusted to different heights to accommodate a wide range of sample sizes. The shelves are designed to be removable, offering users flexibility in arranging the test space. This feature is particularly useful for tests that involve different product configurations or for testing multiple items simultaneously.

Right-Side Access Port: A 125 mm diameter access port is provided on the right side of the chamber for routing cables, sensors, or any external monitoring equipment. The port is equipped with a removable silicone plug, ensuring a tight seal when not in use to maintain the environmental integrity of the chamber.

Left-Side Access Port: A smaller 50 mm diameter access port is located on the left side, offering additional flexibility for routing cables or other testing apparatus. Like the right-side port, it also includes a silicone plug for sealing.

Condensate Drain: A condensate drain is located under the conditioning plenum, which efficiently removes any water or condensation generated during tests with high humidity levels or cooling cycles. This system helps maintain a clean and dry test environment, preventing water accumulation that could interfere with test results or damage equipment.